When it comes to weighing industry terminology, it may be counterintuitive, but “minimum weight” doesn’t actually refer to the smallest amount of weight a scale or balance can measure. So what does it mean? Let’s take a look.

What is Minimum Weight?

Minimum weight is the smallest quantity of matter that can be measured on a weighing device without its uncertainty exceeding the required tolerance. What’s uncertainty? Essentially, it’s the potential range of error in a weighing result.

While uncertainty may seem to be more-or-less the same as error, there’s a key difference. While error is the difference between the actual weight and the measured weight, uncertainty is the estimated difference between them. (For more detail on uncertainty, check out our blog What is the Weighing Uncertainty of a Lab Balance?)

As a sample weight decreases, the percentage error eventually increases to the point where the weighing result isn’t considered accurate enough. In other words, minimum weight refers to how small the weighing result can be before being deemed too unreliable for certain applications. For example, just because a balance’s readability may be 0.001lb, it doesn’t mean you can weigh something that small. It simply means that your weighing results will be in increments of 0.001lb.

Why Do You Need to Know Your Balance’s Minimum Weight?

The point where the reading is deemed unreliable varies by application. For example, weighing ingredients for food preparation wouldn’t use as stringent a standard as a pharmaceutical company weighing ingredients for a medication.

Once the minimum weight for an application is determined, the balance operator must always be certain that a sample doesn’t fall below that minimum.

Different applications require different standards, but one of the most commonly used is United States Pharmacopeia’s USP 41 for the pharmaceuticals industry. That standard governs requirements for balances used in pharmaceutical quality control labs.

Calculating a Balance’s Minimum Weight

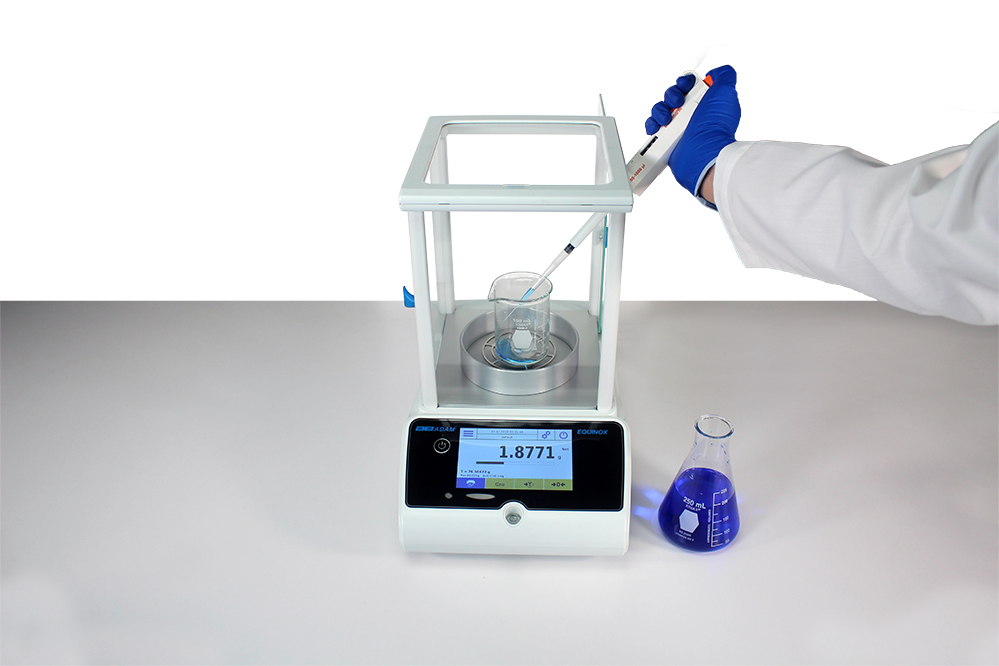

When buying a lab balance, manufacturers don’t always list the device’s minimum weight in the specifications, because that number can vary by application. For Adam, there are generally two rules for minimum weight.

For Adam analytical balances, the minimum weight should be 100 divisions. A division is the readability increment multiplied by 100. For example, has a readability of 0.0001g, so 0.0001 x 100d would be a minimum weight of 0.01g.

are an exception to that rule. Luna follows the USP standard, which increases the minimum weight due to the uncertainty factor. According to the Luna user manual, Luna’s complies with USP minimum weight guidelines of 4000 divisions, which is the standard for the pharmaceutical industry.

The remainder of our product categories (three-place, two-place and one-place) require a 20-division minimum weight. Example: Adam’s offers a 0.5g readability, so 0.5 times 20 would be 10g.

Ultimately, the minimum weight used for each application depends on the user’s own needs and the level of uncertainty they find acceptable. The next step is to select a balance with a readability fine enough to suit those needs.

Need help selecting the right weighing device for yourself or your business? Get in touch with Adam and our staff of trained professionals can help you find a scale or balance to suit your needs!