How to Calibrate a Platform Scale

Platform scales are large industrial platforms used for weighing pallets, containers and other heavy goods. Calibrating platform scales can be tricky without prior experience, and operators need to be comfortable connecting indicators, navigating interfaces and choosing appropriate calibration weights for your scale’s weight capacity. This guide will provide a simple and straightforward way to ensure your platform scales are calibrated correctly every time!

What is weighing scale calibration and why is it important?

Scale calibration is a procedure that ensures that a weighing scale or balance delivers correct, accurate weighing results to the degree specified on the scale. The accuracy of weighing scales can diminish over time through regular use, dust build-up or age; a process often referred to as ‘drift’. For this reason, it is important that scales and balances are regularly maintained.

Trade approved scales certified for selling goods by weight by weighing authorities such as EC, NRCS or NTEP need to be regularly calibrated and checked to ensure they fall in line with legal requirements.

What do I need to calibrate a platform scale?

Platform scales weigh in much higher capacities than standard weighing scales, and therefore require specially designed block calibration weights for accurate external calibration. In the UK and Europe, OIML approved block calibration weights are graded in regards to their tolerance/ level of precision, ranging from M1 to F Class weights. In the USA, ASTM and NIST also have a similar calibration weight grading procedure.

Certain types of scales and balances come complete with internal calibration and do not require calibration weights. However, it is still possible to calibrate platform scales with internal calibration using external calibration weights if necessary.

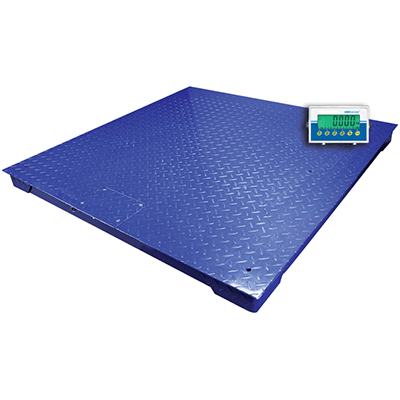

Calibrating Adam’s PT Platform scales with AE403 indicators

Adam platform scales typically follow the same calibration process as standard platform scales, however the indicator interface and accessing calibration modes will differ depending on the type of scale indicator that is used. Here we have included a full description of the calibration process when using Adam’s PT platform scale with Adam AE403 indicators:

|

Step 1 Place the platform base on a flat floor surface, making sure there is plenty of space around the scale base for safe operation. |

|

|

Step 2 Remove anything that has been placed on top of the platform. |

|

|

Step 3 Connect a weighing scale indicator to the platform base using an RS-232 connection cable. |

|

|

Step 4 Power on the indicator and wait it to configure. |

|

|

Step 5 Before configuration is complete, press Tare when the display is showing the countdown for the digits. |

|

|

Step 6 To enter the password, use the directional buttons ⭡ or ⭣ to scroll through numbers 1-9. Use the ⭢ directional key to move to the next digit. |

|

|

Step 7 Enter the correct password [1000] and press [Tare]. |

|

|

Step 8 After pressing [Tare] ↵, ‘noload’ should appear on the display. |

|

|

Step 9 Use the directional button ⭡ to switch to ‘load1’. |

|

|

Step 10 Set the desired weight limit of the test object to be placed on the scale using the ⭡ or ⭣ directional buttons and the ⭢ directional key to move to the next digit. |

|

|

Step 11 Once you have selected the desired weight limit of the test object, press the [Tare] ↵ key to confirm. |

|

|

Step 12 The display will show 'load'. Load the desired weight onto the platform. |

|

|

Step 13 Once the weight is on the platform press the [Tare] key to confirm. |

|

|

Step 14 Once confirmed, the indicator will enter the configuration process. When the process is complete the indicator will show the desired weight currently on the platform. |

|