As sustainability takes on an ever-growing role in industrial facilities around the world, recycling is developing faster than ever. It’s increasingly more important to be able to reuse, to reduce and to dispose of waste materials properly. Weighing equipment is one of the many tools used in the recycling industry, from small operation to national facilities. In this post, we’ll help you learn more about using weighing to streamline recycling operations, and how to pick the best equipment for the job.

Why Weigh Materials that Need to Be Recycled?

As we’ve written before, using a scale properly can considerably reduce material waste in various operations. Recycling and waste disposal are not as easy as we might think, and it’s important to be able to optimize the thin margin between recyclable materials and waste products. Measuring waste also can help businesses understand just how much they produce, and how to properly reduce the practices that lead to more waste. Proper management of these resources can save time and money.

Waste disposal requires transportation, and proper weight management can save wear and tear for vehicles and industrial machinery processing various materials, as well as fuel.

Some operations, especially businesses that deal with scrap metals, can sell recyclable waste, so accurate weighing is paramount if they want to make money.

Does the Scale Need Trade Approval?

That depends. Salvage operations and recycling plants that sell or buy materials for reuse do need trade approved scales. For high volumes, a trade-approved indicator with a large platform combines heavy-duty capacities with commercial precision. Some waste management businesses need approved scales as well if they deal with specific materials and substances, especially in the disposal phase. It’s important to fully read and apply the laws in your region of the world, as well as local regulations. Some municipalities might charge residents to dispose of sizeable items or specific materials, in which case a trade-approved scale must be used in order to ensure residents are getting a fair deal, and that the local waste management plant is not under or overcharging.

Which types of scales are used in the recycling industry?

In addition to large weighing systems attached to trucks or bridges, medium and small-scale operations, as well as the later part of the recycling process, use various types of scales to weigh waste.

Pallet truck scales are used to measure bundled waste or materials placed on pallets. They allow workers to transport the waste as well as weigh it in a seamless manner. Using a pallet truck scale means workers don’t have to unload the waste, place it on a platform, weigh it then place it on a pallet. That can help save a lot of time and effort in the long run and can help prevent injuries by eliminating unnecessary steps in the process. Despite their high capacity, they don’t take much space and can be very maneuverable even in tight corners. Adam’s PTSplus features non-marring wheels to keep floor clean, and a handle with a zero-radius pivot for superior maneuverability.

Heavy-duty platforms are often used in conjunction with indicators. They can handle very high capacities and rigorous usage, and they’re designed to be easy to clean. Ramps and a low profile facilitate loading and unloading, whether by placing waste on the platform or rolling drums of liquid waste products. If you weigh waste in containers or bins, be sure to get a platform or weighing beams that can accommodate their combined weight. Our AELP beams can handle up to 3000kg while our PT platforms go as high as 4500kg.

Bench scales are also used by recycling plants to measure paper or plastics, while floor scales are used for heavier materials such as glass or metal.

Crane scales can be integrated in various processes to weigh suspended materials. They allow for remote-controlled operation to improve safety. Our IHS crane scales can weigh up to 5000kg.

Be careful! When weighing heavy objects, remember the container’s weight counts, even if it’s tared. Take that into consideration when choosing a scale to avoid damaging inner components and mechanisms. And be sure to always take security precautions.

What are the benefits of using scales in the recycling industry?

When they’re properly integrated, scales can save considerable amounts of time and money, and can help improve safety. One of the many reasons to use digital scales lies in their ability to connect to computers and printers, so data can be transmitted directly without having employees stop what they’re doing to transcribe weight data. This can improve safety as well since employees can spend less time handling potentially dangerous materials. Productivity is also a factor because employees often juggle many different responsibilities that could be slowed down by the need for data entry.

Managers and analysts can track waste as it is processed and streamline operations to improve productivity using that data.

Some companies buy waste to recycle them into materials used for manufacturing (the most common are metal, paper, glass, and some types of plastics). Using weight can give a more accurate understanding of the amount of materials purchased and make sure both buyer and seller get fair prices. Filling a container is heavily dependent on the type of material and the shape it’s in (for example, if someone is buying glass, bottles take more space than crushed glass). In some countries, certain types of waste must be disposed of by specialized companies and weight determines the cost of the disposal efforts.

Which features are important?

Data communication is paramount for computerized management and integration with software. Even for small plants, being able to track this data can save immense amounts of time and money. Adam scales include standard RS-232 interfaces, and some scale models also include USB ports. RS-232 to USB connectors are also available if needed.

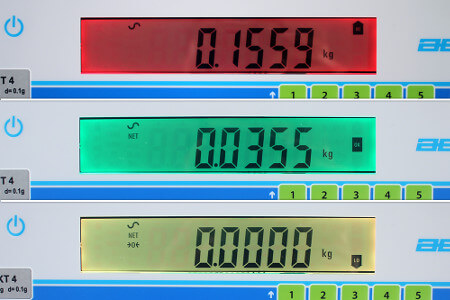

A brightly visible display is important because the results must always be clearly visible, and from a distance. Some Adam scales include programmable displays to help conserve battery life or to make sure the display is always brightly lit during operations.

Checkweighing can be useful when batching lots to be recycled, filling containers, or making sure truck and machinery is not over capacity and damaged from overloads.

Depending on the waste type, a scale with an IP rating of 67 or 68 for easy cleaning can help maintain hygiene protocols and speed up cleaning tasks. Adam platforms are available in stainless steel or diamond plate surface for your convenience.

Obviously, the weighing equipment needs to be sturdy and able to handle daily rigorous usage. Solid metal construction and shielded cables or components are necessities. Overload protection can help busy recycling centers protect their weighing equipment even if they’re over capacity.

The tare feature can be useful for waste in bins and containers. Some scales and indicators can even store preset tares for frequently used containers to save time.

Label printing can be very useful to track waste’s point of origin, when bundling waste products together or simply to keep track of things that need to be transported and processed. Our label-printing scales and indicators include software to edit and customize labels as you see fit, so you can even add logos, bar codes, QR codes and various pieces of information.

Do you need help choosing the right weighing solution for your recycling plant? Contact us, we’ll be happy to answer any question you might have.