Pharmaceutical drugs are continually being discovered, developed and manufactured. Scales and balances are a key part of the process, from conception to your medicine cabinet. They provide precise measurements that help guarantee the medications on the market are the safest and most effective they could possibly be. In this blog, we’ll discuss where you’ll find scales and balances making a difference.

The Process & Timeline

Potential drugs endure a long, through research and testing process, lasting up to 20 years and costing up to a billion dollars. Like a funnel, fewer and fewer drugs progress through to the next stage each time, with most being eliminated in preclinical and phase 1 clinical trials. This ensures only the best, most effective are released to the public. Here’s the general process and timeline:

Identification

- Pharmaceutical scientists work to identify a compound (a substance formed from two or more chemical elements) against diseases, viruses or conditions

- The goal is for the compound to have a positive impact and eventually ease symptoms or provide a cure, without harm to the human body

- Lasts an average of four years

Preclinical Trials

- Test the compound on animals to get information on how the drug may work in humans

- Help develop a base understanding of potential potency (concentration), efficacy (ability) and toxicity (side effects)

- Take an average of two years

Clinical Trials

After preclinical testing on animals, the US Food and Drug Administration (FDA) or the European Medicines Agency (EMA) in the EU must approve the jump to testing on humans. If it’s approved, it then moves through a further three phases. Throughout each, scientists attempt to further their understanding of the drug, reconfirm previously established details and justify testing more people in the next phase.

Phase 1

- Human testing with a relatively small group of healthy volunteers (20 – 100)

- Establishes the safety and proper dose

- Ranges from several months to two years

Phase 2

- Human testing with a larger group of volunteers (100-300) that actively suffer from the targeted disease or condition

- Establishes efficacy and side effects to confirm safety

- Takes anywhere from several months to two years

Phase 3

- Human testing with a large group of patient volunteers (300 – 3000)

- Compares the efficacy and safety of the potential drug against what’s currently used to treat the targeted disease, virus or condition

- Establishes how the drug interacts with other drugs and comorbidities, or diseases and conditions beyond those the drug seeks to treat

- Attempts to prove that the drug is safe, beneficial and effective

- Lasts between two to four years

FDA/EMA Review

- The FDA or EMA reviews all trial and test results on both animals and humans

- The FDA or EMA decide whether the drug can be officially released to the public

- The review process takes between six to ten months, though some can be expedited if they’re high priority

Phase 4

- Occurs after approval by the FDA or EMA, manufacturing and distribution

- Performs long-term surveillance to study risks after long-term use

- Observes the efficacy of the drug during normal, widely varied everyday life

- Monitors for up to 15 years after distribution

How Are Scales and Balances Used in the Drug Development Process?

Now that we know the general process of a drug’s development, we’ll get into what areas you’ll find scales and balances most often.

Assist in Establishing Potency and Efficacy

A drug’s potency refers to the dose necessary to provide the level of response they’re looking for. Determining a drug’s potency involves precisely weighing compounds and testing them until the desired response is achieved. A drug’s potency is an important indicator of its potential dose – you may have noticed that most drugs are sold or prescribed in milligrams. Weighing solid compounds instead of measuring by volume offers more consistency and ensures that anyone with the precise recipe can reliably recreate it.

A drug’s efficacy is how effective it is at producing the desired response. A drug’s efficacy may be what makes or breaks its overall approval. It may take 2mg of a specific compound to begin degrading or killing diseased cells (a high potency), but if it doesn’t do it well, for example, only kills a fifth of the necessary cells, then it offers an insufficient efficacy.

Efficacy is relative to the problem you’re trying to solve – if you’re looking to completely relieve severe pain and produce a euphoric sensation, Acetaminophen won’t cut it, it has a low efficacy compared to a drug like Morphine. However, if you’re looking to relieve everyday aches and pains, Acetaminophen has a great efficacy and Morphine is overkill.

When dealing with such small quantities of chemicals, a semi-micro or analytical balance such as would be the best choice. The Equinox EAB offers readabilities as fine as 0.01mg and boasts a formulation function. This allows pharmaceutical scientists to create and store formulas for compounds with ingredients and tolerances. Without the precision of analytical and semi-micro balances, accurately determining a drug’s potency would be nearly impossible, which would make the whole development process much more difficult and more likely to fail.

The EAB connects easily to a or computer and provides GLP compliant data including date, time, user ID and more to ensure full traceability.

Help Develop Reliable Doses

As mentioned above, a drug’s potency is an indicator of its dose, or how much is recommended for someone to use. Potency essentially establishes the bare minimum requirement. To truly establish the correct dose, factors including a patient’s body weight must be considered. Body weight impacts how medicine is distributed throughout the body and how quickly it’s metabolized. An example you may recognize is that those with a higher body weight can handle quite a bit more alcohol than those of a lower body weight.

When presenting information to the FDA/EMA during the approval process, they’re going to want to see evidence of how the drug interacts with people of different weights, especially if they’re intending to market the drug to both children and adults.

Some drugs may be sold in a standardized dose because they’re not easy to overdose on and don’t cause any significant side effects, so scientists can effectively assume “one size fits all,” except for extreme circumstances. Others, like insulin for diabetics, will always have to have the dose adjusted per person, which is called an individualized dose, because the patient’s body weight and metabolism play such a heavy role.

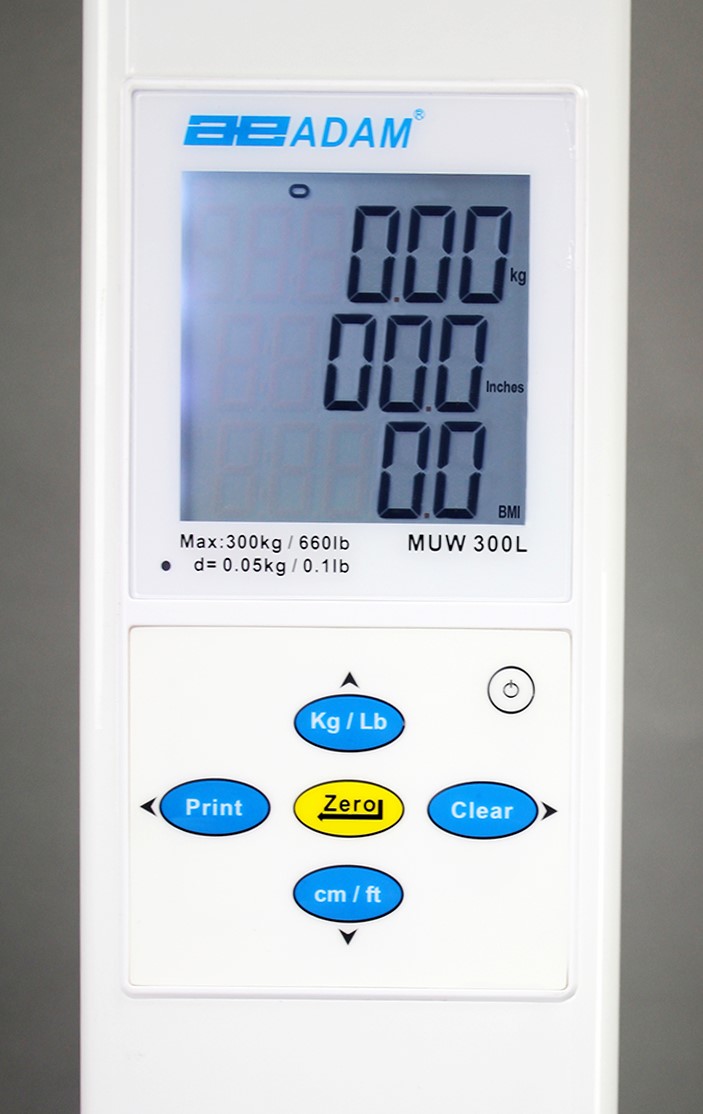

For weighing volunteers, Adam Equipment’s MUW is the ideal tool. The can simultaneously collect weight, height and BMI data using ultrasonic sensors, improving efficiency. An RS-232 interface allows for connection to computers and printers such as our to maintain traceable records.

The provided dose would need to be measured extremely carefully with an Analytical or Semi-Micro Balance like the Equinox or Adam Equipment’s . Inconsistency can render the trials useless and prevent the drug’s approval.

Maintain Effective Quality Control

Once the drug has been approved and it’s being manufactured, spot testing for quality control is very important. A precision balance is likely enough, such as Adam’s or , with readabilities between 0.001g and 0.1g. Though not required, the Trade Approved Highland lends credibility for applications where weight quality needs assurance, as NTEP approved balances meet the standards and requirements of state testing.

The weight of a medication after it’s been produced is one of the most important qualities to double check before continuing the manufacturing process. By this point, every pill or tablet produced should contain exactly the right amount of active ingredient. If quality control notices that a batch of medicine is commonly weighing 320mg instead of 300mg, this could be enough to scrap the batch.

Performing quality control with precision balances ensures that consumers aren’t using medicine in incorrect doses that can lead to ineffective treatment or an increase of harmful side effects.

The correct moisture content in pharmaceuticals is also crucial – you can read our blog on the topic by clicking here.

Medicines are dosed by weight, so they should be measured by the most accurate Adam Equipment scales and balances. For more help selecting the right balance, contact us and we’ll be happy to help.