Highly precise results require quite an effort – many factors can influence your analytical balance and cause inaccurate readings. In this blog, we’ll discuss two of the lesser-known influences, heat and updrafts, and how our new Polaris range solves the problem.

Heat

All scales and balances are impacted by extreme temperatures, as metal and plastic expand or contract when hot or cold. However, highly sensitive semi-micro analytical balances, like the new Polaris PAB 125i model, can be affected by even slight temperature fluctuations. This makes maintaining a well-regulated laboratory crucial to obtaining accurate weight readings.

The National Institute of Standards and Technology (NIST) states that serious effort should be made to ensure that temperatures reach an equilibrium between the balance, environment and any samples. Once a weighing session has started, it’s equally important to guarantee that temperatures within the room don’t vary more than about 0.9 degrees Fahrenheit or 0.5 degrees Celsius. Leaving the balance, samples and any tools like calibration weights near each other for a while helps them acclimatize to the ambient temperatures, helping to prevent your results from drifting.

To go a little further, humidity is also an influence. A relative humidity percentage of less than 40% can generate static near or even in the balance. This also causes inaccurate results, though the display is more likely to jump than drift. Luckily, accessories such as Adam’s can help neutralize static electricity in particularly dry environments.

Updrafts

Air currents are a well-known agitator for semi-micro and analytical balances, which is why all of them come pre-fitted with a draft shield. This helps protect against outside air currents, but many don’t realize that air currents can develop within the draft shield as well. Temperature variations between the balance and the sample being weighed can create convection currents that influence results even with a draft shield.

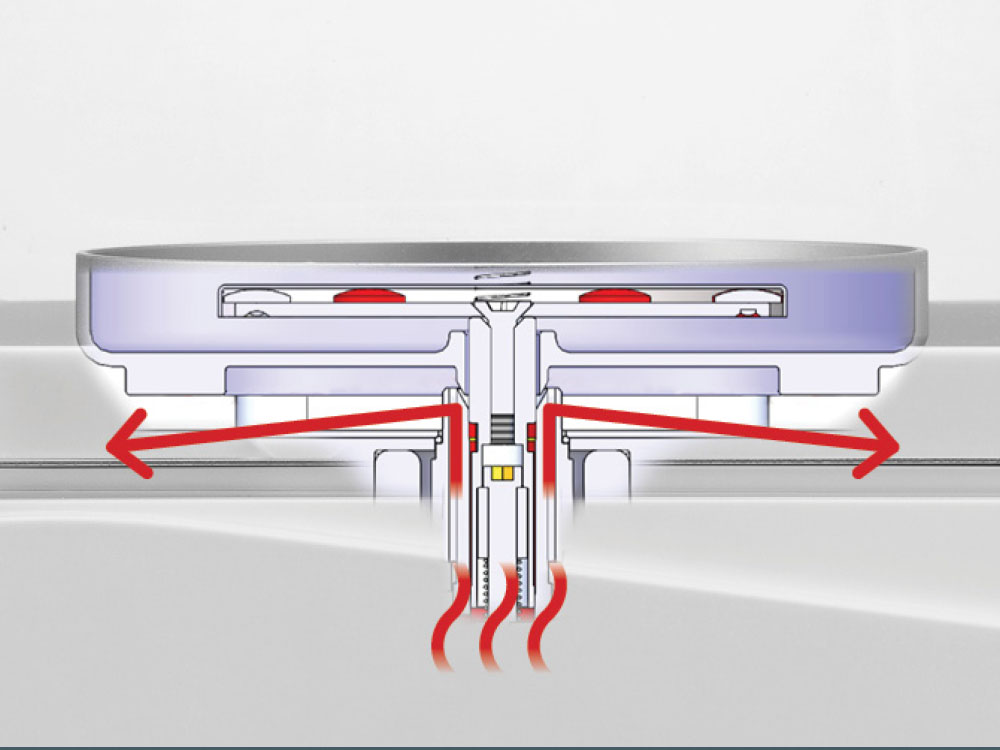

Unfortunately, sometimes this is unavoidable – many don’t know that as the balance is being used, the internal mechanisms begin to generate their own heat. Because heat rises, the natural consequence of this is that the heated air ends up emerging through the weighing pan and into the draft shield. This can cause enough of a temperature fluctuation to create a convection current and disrupt your weighing results.

Air Diversion Technology

Adam’s Polaris PAB 125i Semi-Micro Analytical Balance, available now, offers a unique Air Diversion Technology (ADT) feature. It was developed to combat heat from the internal mechanisms rising and creating convection currents. Channels beneath the weighing platform divert the heat away from the weighing pan, as depicted in the diagram below. With Polaris, you can be sure that your results are reliable throughout every weighing session.

Excited about the Polaris? Learn more about the range here. In the meantime, you can contact the Adam team with any questions, we’ll be happy to help.