Weighing devices used for commercial or laboratory use are often designated within accuracy classes, which are usually referred to simply as classes. What do these classifications mean? Let’s take a look!

Scale Divisions

We can’t talk about classes without first discussing scale divisions. A scale division is the smallest subdivision or unit that can be indicated by a scale’s digital display. It’s a term commonly used interchangeably with readability or resolution.

Division can be determined by dividing the scale’s capacity by its readability. If you have a scale with a 1000lb capacity and a 0.1lb readability (1000 divided by 0.1) has 10,000 divisions. In this example, if you have items that each weighed 0.1lb / 0.05kg, you would be able to put 10,000 of them on the scale before you reached the maximum capacity of that scale. The same goes if you have a scale with a 5000kg capacity and a 0.5kg readability; 5000 divided by 0.5 is 10,000 divisions.

Discussion of scale divisions often includes reference to “d” and “e” values. The “d” refers to the value of the scale division, while the more precise “e” refers to the verification scale division. Used mainly for commercial transactions, “e” is the smallest approved scale increment that can be used to determine a selling price by weight.

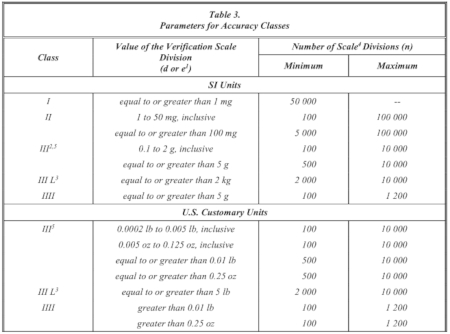

Accuracy Class Chart from NIST Handbook 44

The class definitions remain the same globally (though some countries may refer to Class I, for example, as Special class, as noted in the headings below). Universal definitions like this can promote collaboration, as well as simplify scientific and commercial applications. Click here for a handy infographic.

Class I/Special

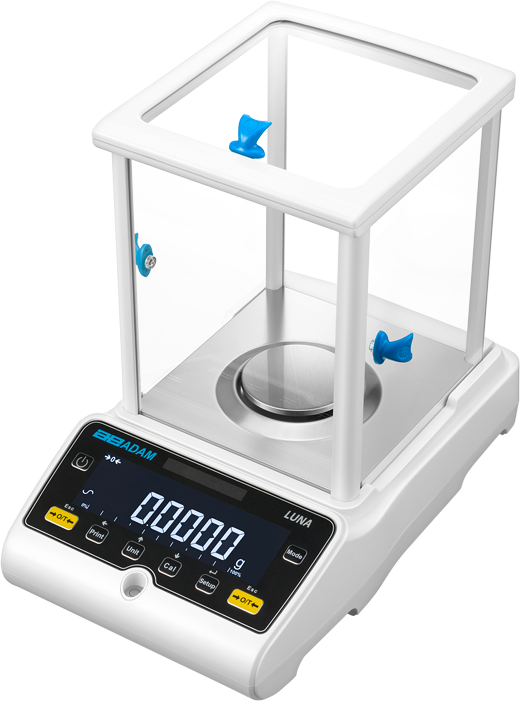

Class I scales, which are ideal for precision lab work, have a minimum of 50,000 divisions. They display results in increments of 1mg or better. Semi-micro and analytical balances like the and are often rated Class I.

Class II/High

Class II scales have up to 100,000 divisions. Typical uses include laboratory weighing, weighing of precious metals and gems, and grain test scales.

Our is an example of a Class II balance. The , which is legal-for-trade in the U.S. and Europe, is often used in jewelry industry and legal botanical dispensaries. Because of the high price (by weight) of goods like gems or botanicals for small amounts, a Class II weighing device is required to ensure a fair exchange for both the buyer and seller.

Class III/Medium

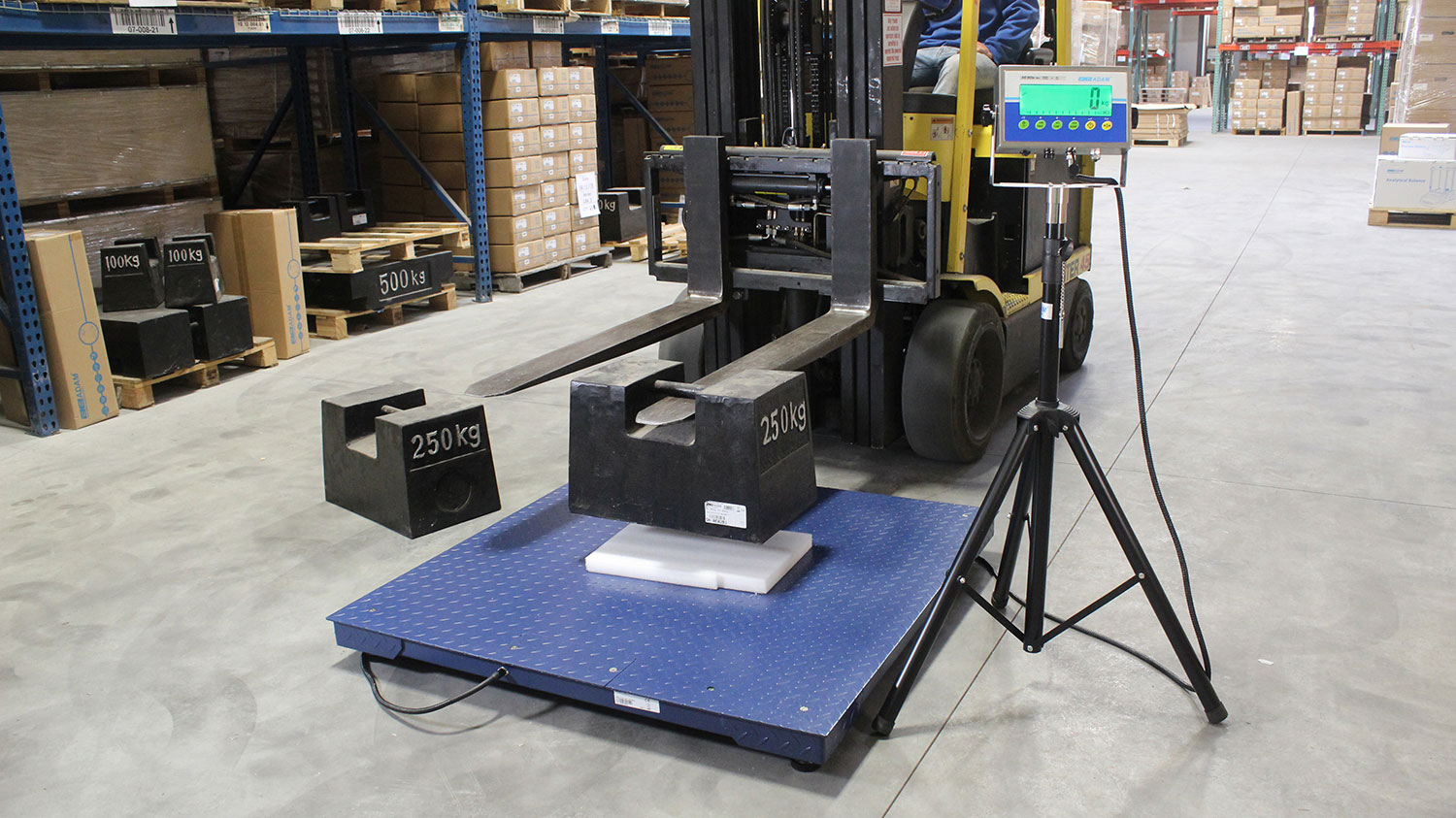

Class III scales are designed for industrial or commercial use, including tasks like animal weighing, food weighing, postal use, scales used to determine laundry charges and vehicle on-board weighing systems (with capacities up to 30,000 lbs / 13,607 kg). They have a maximum of 10,000 divisions.

Scales like Adam’s , when paired with weight indicators, are Class III.

Class III L

Like Class III scales, Class III L are also used for commercial use, but they offer a much larger capacity and are used for weighing vehicles, axle loads, livestock, railway tracks, vehicle on-board weighing systems (with capacities greater than 30,000 lbs / 13,607 kg), cranes and hoppers (other than grain). Like the standard Class III scales, they also have a maximum of 10,000 divisions.

Class IIII/Ordinary

Class IIII – wheel-load weighers and portable axle-load weighers used for highway weight enforcement – have up to 1,200 divisions.

How Do Accuracy Classes Relate to Trade Approval?

Whether NTEP, Measurement Canada, CE, OIML, NMI or NRCS, trade approvals rely on the “e” verification scale division.

While not all weighing devices must be legal-for-trade, the trade approvals do use accuracy class standards as part of their approval process.

If you have any questions about how Adam products are classified or you need a weighing device in a certain class, ask us!