Weighing In on Calibration Weights

You’ve invested in a good quality balance for your lab or bench scale for your warehouse and you need a set of calibration weights to ensure the integrity of your weighing results. Where do you start?

ASTM & OIML Weight: What’s the Difference?

The first thing to consider when purchasing a calibration set is where you’ll be using it. If you’re in the United States, you’ll likely be using an ASTM set. Outside the U.S., OIML weights are typically used. If you’re working both within the United States and internationally, it may be worth investing in both types. (Check with your Adam sales representative to see if both types are offered in your region.)

The standards were created by two different organizations: ASTM International (formerly known as the American Society for Testing & Materials) and OIML (the International Organization of Legal Metrology).

Adam’s ASTM and OIML weights are made from highly polished stainless steel. In addition, Adam offers a selection of cast iron OIML weights for larger scales.

Weight Classes

In the U.S., Adam Equipment offers individual ASTM weights and weight sets in Classes 0 through 4, meeting the requirements of ANSI/ASTM. Higher class numbers indicate higher levels of tolerance (i.e., lower accuracy). Most lab applications require ASTM weights of Class 4 or below.

- Class 0: a primary reference standard for calibrating other reference standards and weights

- Class 1: used as a reference standard for lower-tolerance weights, as well as for calibrating analytical balances with readabilities as low as 0.1mg to 0.01 mg

- Class 2: used for calibrating precision balances with readabilities as low as 0.01g to 0.001g

- Class 3: used for calibrating precision balances with readabilities as low as 0.1g to 0.01g

- Class 4: used for calibrating low precision lab balances, as well as student use

ASTM standards also include Class 000 and Class 00 (primary references for calibrating other reference standards and weights), Class 5 (student laboratory use), Class 6 (which meets the specifications of OIML R111 Class M2) and Class 7 (rough weighing operations in physical and chemical labs).

OIML’s highest-accuracy weight, Class E0, is used for traceability between national mass standards and weights of lower classes. Worldwide, Adam offers individual OIML weights and weight sets in Classes E1, E2, F1 and M1. (Class E1 is not available in the U.S.)

- Class E1: used for traceability between national mass standards and weights of Class E2 and lower, as well as calibrating semi-micro balances

- Class E2: used for traceability between national mass standards and weights of Class F1 and lower, as well as calibrating analytical balances with readabilities as low as 0.1mg to 0.01mg

- Class F1: used for traceability between national mass standards and weights of Class F2 and lower, as well as calibrating precision balances with readabilities as low as 0.01g to 0.001g

- Class M1: affordable weights used for general laboratory and industrial applications. M1 weights may be used for calibrating compact portable balances and bench scales, as well as for traceability between national mass standards and weights of Class M2 and M3.

For ASTM and OIML weight tolerances, click here. To see the range of weights offered by Adam, click on ASTM or OIML.

When purchasing weights from Adam, individual weights are packaged in a plastic box. Weight sets come in a lined aluminum box, which includes tweezers (sometimes referred to as forceps) and a white cotton glove.

Internal Calibration & Calibration Weights

Obviously if your weighing device is labelled “external calibration,” you’ll need calibration weights for verification. Internal calibration is pretty clear – the balance features internal components that are used to calibrate it. But wait – do you still need calibration weights if your balance offers internal calibration?

It’s not strictly necessary, but it doesn’t hurt. Most internal calibration weighing devices use a smaller reference weight but using an external weight for calibration allows the scale to be calibrated to its full capacity. Using an external weight can also verify the integrity of the scale’s internal calibration process.

Caring for Calibration Weights

We’ve covered how to care for calibration weights in a previous blog post and a refresher can often be helpful. For 5 Tips on Caring for Calibrations weights, click here.

Calibration weights are extremely sensitive. To protect the surface of your weights from fingerprints, oil and foreign material like dust or lint, always wear gloves when handling them. For further protection, use large weight tweezers or small weight tweezers.

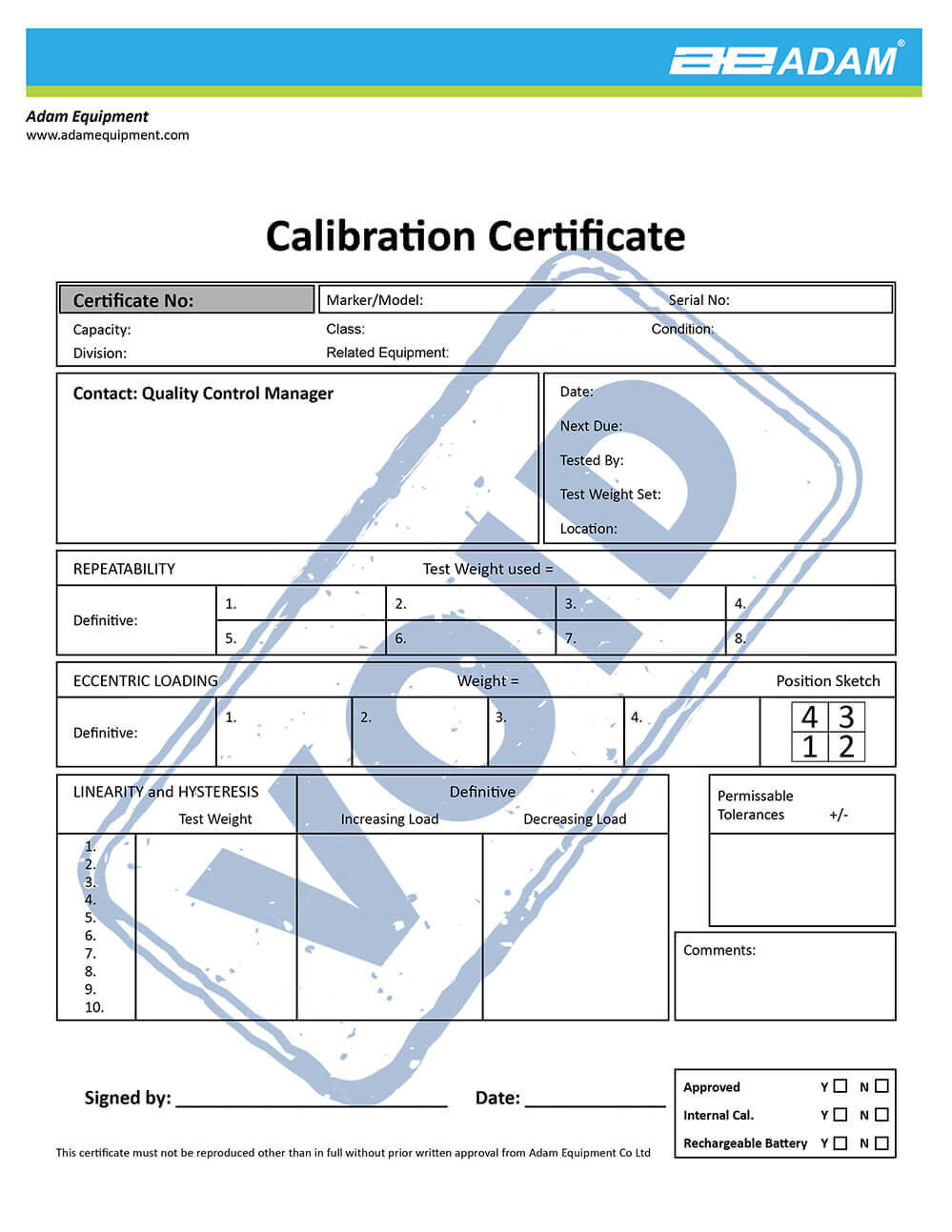

Certificates

Along with our scales and balances, customers may also buy a calibration certificate at the time of purchase to certify that the device has been calibrated and is within tolerance.

Calibration weights must be traceable to the kilogram (the SI unit for mass) and certifications may also be purchased for the weights. Adam’s U.K. office offers the certification, while Adam’s U.S. office can provide metrology lab recommendations for customers to obtain a certification.

Certifications include an accredited Certificate of Weight Calibration, a non- accredited Certificate of Weight Calibration and a Statement of Accuracy (not a traceable document).

Contact us with any questions or if you need assistance in choosing the right calibration weights for your needs!